WHY UDT

BECAUSE WE USE ONLY HIGH-QUALITY MATERIALS !!!

What Is Steel?

Steel is an alloy metal composed of iron and varying amounts of carbon and/or other elements such as chromium, nickel, tungsten, manganese, and so on. Steel with specific properties and characteristics is created by adjusting the overall chemical composition or by altering the various production processes such as rolling, finishing, and heat treatment. Because each of these factors can be modified, there is potentially no limit to the number of different steel recipes that can be created. Currently, there are over 3,000 catalogued grades or chemical compositions of steel available. Steel can utilize a wide variety of alloying elements and heat treatments to develop the most desirable combination of properties.

Steel Hardness and Quality

For steel targets to be functional and safe, they should be made of high quality through hardened steel that has a Brinell hardness number (BHN) of at least 500. The steel must also provide sufficient strength, toughness, and impact resistance. The Brinell hardness test depends upon the resistance offered to the penetration of a carbide steel ball (1.6 mm diameter) when subjected to a weight of 12.6 kg. The resulting hardness value is computed as the ratio of the applied load to the area of the indentation produced. This test is accepted as a worldwide standard for measuring the hardness of steel.

Truth – There are 2 Factors that Affect the Hardness of Steel

The first is the amount of carbon and other alloying elements in its chemical composition, and the second is the manner in which the heating and cooling of the steel is manipulated. These factors are determined at the most fundamental level, and affect the finished steel as a whole.

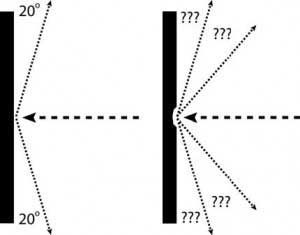

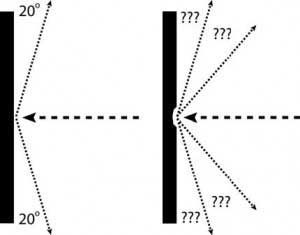

[Left] Hard steel with a flat surface will create a predictable splatter pattern. [Right] Soft steel with an uneven surface will cause unpredictable and unsafe ricochet and splatter.

Truth – Steel Hardness is a Critical Issue

The hardness of the steel is critical because only a smooth surface will generate predictable splatter patterns. Steel that is not sufficiently hard can develop pits, craters, dimples, and other hazardous deformations. When a bullet hits one of these deformations, it is impossible to predict where the splatter will go, thereby creating an unacceptable training environment. There are many steel mills located around the world, but only a select few are able to produce steel that is hard enough and of sufficient quality to be safely used for steel targets.

What Is Steel?

Steel is an alloy metal composed of iron and varying amounts of carbon and/or other elements such as chromium, nickel, tungsten, manganese, and so on. Steel with specific properties and characteristics is created by adjusting the overall chemical composition or by altering the various production processes such as rolling, finishing, and heat treatment. Because each of these factors can be modified, there is potentially no limit to the number of different steel recipes that can be created. Currently, there are over 3,000 catalogued grades or chemical compositions of steel available. Steel can utilize a wide variety of alloying elements and heat treatments to develop the most desirable combination of properties.

Steel Hardness and Quality

For steel targets to be functional and safe, they should be made of high quality through hardened steel that has a Brinell hardness number (BHN) of at least 500. The steel must also provide sufficient strength, toughness, and impact resistance. The Brinell hardness test depends upon the resistance offered to the penetration of a carbide steel ball (1.6 mm diameter) when subjected to a weight of 12.6 kg. The resulting hardness value is computed as the ratio of the applied load to the area of the indentation produced. This test is accepted as a worldwide standard for measuring the hardness of steel.

Truth – There are 2 Factors that Affect the Hardness of Steel

The first is the amount of carbon and other alloying elements in its chemical composition, and the second is the manner in which the heating and cooling of the steel is manipulated. These factors are determined at the most fundamental level, and affect the finished steel as a whole.

[Left] Hard steel with a flat surface will create a predictable splatter pattern. [Right] Soft steel with an uneven surface will cause unpredictable and unsafe ricochet and splatter.

Truth – Steel Hardness is a Critical Issue

The hardness of the steel is critical because only a smooth surface will generate predictable splatter patterns. Steel that is not sufficiently hard can develop pits, craters, dimples, and other hazardous deformations. When a bullet hits one of these deformations, it is impossible to predict where the splatter will go, thereby creating an unacceptable training environment. There are many steel mills located around the world, but only a select few are able to produce steel that is hard enough and of sufficient quality to be safely used for steel targets.